Station I

Cardboard Positioning

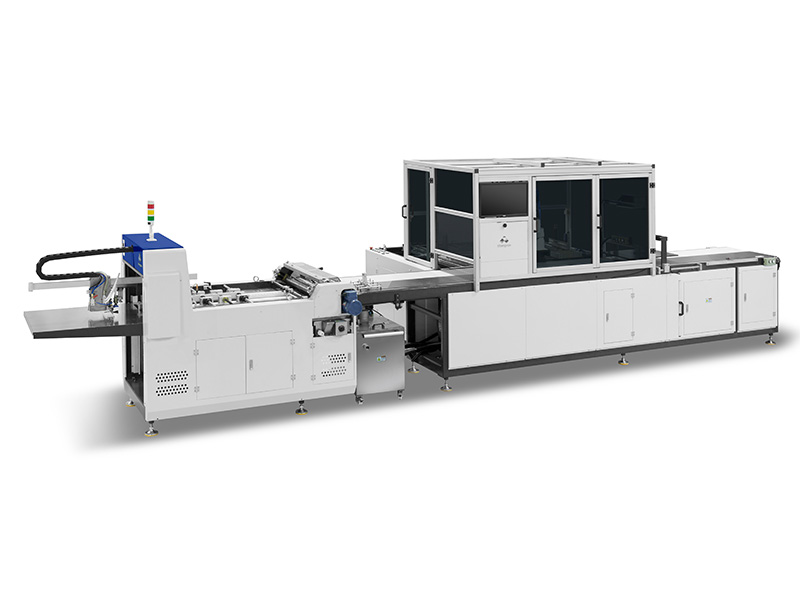

It Can automatically feed and glue paper, delivery and position cardboard,and fold four sides in one process; there are features of accurate and quick positioning, and beautiful finished products etc.

≤35

boxs / min

It is used to make hardcovers, notebook covers, desk calendars, hanging calendars, book-type boxes, files and rregular covers etc.

The paper carton erecting machine is an ideal choice to produce hamburger boxes,chips boxes, take away box, etc. It adopts micro-computer, PLC, servo feeding, alternating current frequency converter, the vacuum-sucking, auto gluing, automatic paper tape counting, chain drive. All of these main parts and electric control system adopts famous brand to guarantee steady working, precise positioning, smooth running, safety and reliability operation. It can make more than 10 types of boxes. Pls let us know if your box is not in blew list. The paper rectifying device ensures that the paper is not offset after gluing.

| Model |

CB540 |

| Case Size (W×L) | Min.100×200mm Max.540×1000mm |

| Box Size (W×L) | Min.50×100mm Max.360×480mm |

| Box Height (H) | 10-120mm |

| Paper Size (W×L) | Min.100×200mm Max. 570×1030mm |

| Paper Thickness | 100-300g/m² |

| Cardboard Thickness (T) | 1-4mm |

| Precision | ±0.1mm |

| speed | ≤35pcs/min |

| Motor Power | 8kw/380v 3phase |

| Electric Heating Power | 12kw |

| Air Supply | 10L/min 0.6Mpa |

| Machine Dimension | L7350×W3520×H2000mm |

| Machine Weight | 2200kg |

Cardboard Positioning

Box Positioning The first domestic three-camera positioning system.

We have the latest advanced processingequipment and international lean productionprocess, and strive to be the industry leader.