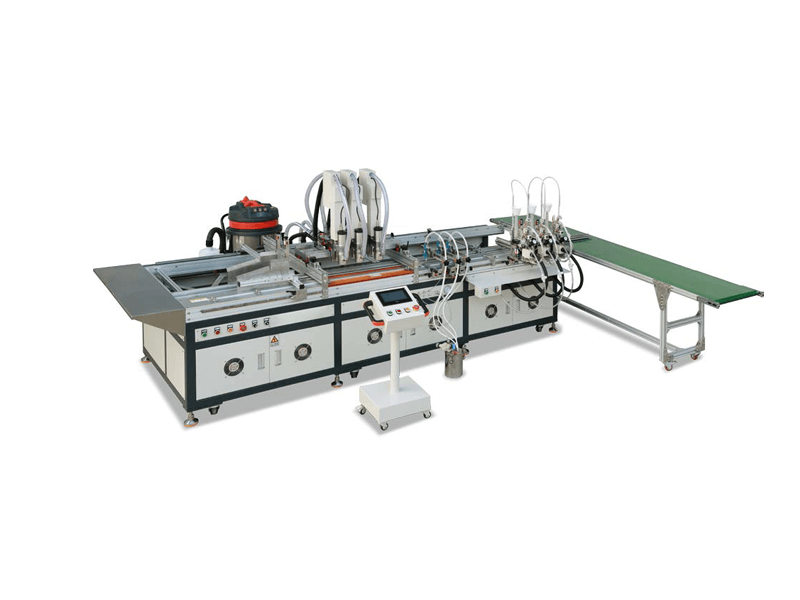

The output of this model can reach 1500 ~ 1800PS/ hour, greatly saving labor, single one person operation can be. The use of high precision workpiece, configuration of high stability performance electrical components, ensure the machine in the production process of reliable and safe operation, improve the service life of the machine at the same time, simple control and man-machine interface friendly communication.

30~40

boxs / min

In addition, it has the function of fault alarm and automatic shutdown, and sends out fault prompt information.

1、Feeding features: According to different thickness of different specifications of the board to adjust to ensure smooth and stable product feeding.

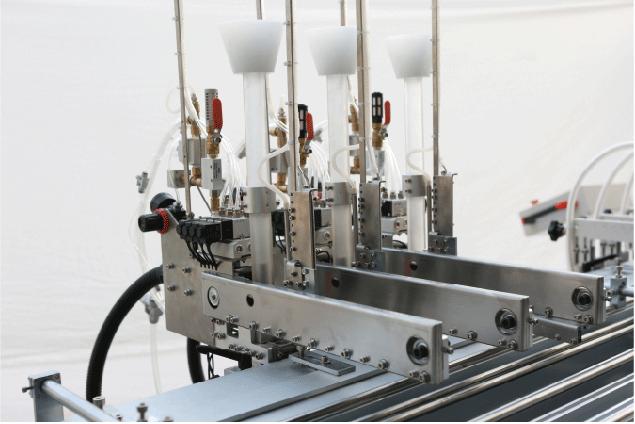

2、Drilling part features: automatic drilling, equipped with automatic vacuum cleaner and blower system, depth and diameter of dilling can be flexibly adjusted to change the uneven situation when manually picking holes.

3、Dispensing part features. the size and position of the glue can be adjusted according to the product, effectiely solve the problem of dispensing is not allowed and glue overflow.

4、Magnet (iron sheet) part features: at the same time can stick 1, 2, 3 magnets (iron sheet), position adjustable, speed adjustable, pressure adjustable, single and double sheet program can be set.

We have the latest advanced processingequipment and international lean productionprocess, and strive to be the industry leader.