In the world of packaging, the demand for high-quality, durable, and visually appealing boxes is ever-growing. Whether it's for luxury goods, electronics, or retail products, the need for precision and efficiency in box production has led to the development of advanced machinery. One such machine that has revolutionized the industry is the Automatic Rigid Box Maker. If you're in the business of creating rigid boxes, understanding this machine and its capabilities is essential. In this article, we’ll explore what an Automatic Rigid Box Maker is, how it works, and why it’s the go-to machine for producing high-quality boxes.

An Automatic Rigid Box Maker is a specialized piece of equipment designed to manufacture rigid boxes with minimal human intervention. Rigid boxes, also known as set-up boxes, are known for their sturdiness and premium finish. They are commonly used for high-end products such as luxury cosmetics, electronics, jewelry, and gift packaging. Unlike folding cartons, rigid boxes are made from thick, non-bending materials like chipboard, which require specialized machinery to assemble.

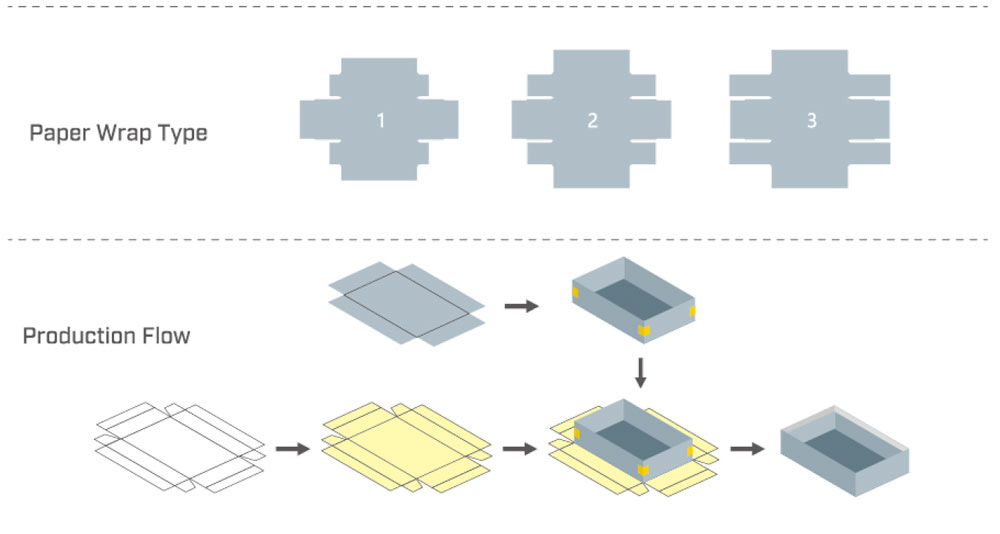

The Automatic Rigid Box Maker streamlines the entire production process, from cutting and creasing to gluing and assembling. It is capable of handling multiple steps in the box-making process, ensuring consistency, precision, and speed.

1.High-Speed Production

Automatic Rigid Box Makers are designed for efficiency. They can produce hundreds or even thousands of boxes per hour, depending on the model and complexity of the design. This makes them ideal for large-scale production.

2.Precision Cutting and Creasing

These machines are equipped with advanced cutting and creasing tools that ensure each box is made to exact specifications. This is crucial for maintaining the quality and consistency of rigid boxes.

3.Versatility

Automatic Rigid Box Makers can handle a wide range of materials, including chipboard, paper, and fabric. They can also produce boxes of various shapes and sizes, making them suitable for different industries.

4.Automated Gluing and Folding

The machine automates the gluing and folding processes, ensuring that each box is assembled perfectly. This eliminates the risk of human error and reduces labor costs.

5.User-Friendly Interface

Modern Automatic Rigid Box Makers come with intuitive control panels that allow operators to easily adjust settings, monitor production, and troubleshoot issues.

The operation of an Automatic Rigid Box Maker can be broken down into several key steps:

1.Material Feeding

The machine is loaded with the raw materials, such as chipboard and covering paper. These materials are fed into the machine automatically.

2.Cutting and Creasing

The machine uses precision blades and creasing tools to cut the chipboard into the desired shape and create fold lines.

3.Covering and Gluing

The covering material (e.g., paper or fabric) is applied to the chipboard using an automated gluing system. The machine ensures that the material is evenly spread and securely attached.

4.Folding and Assembling

The machine folds the chipboard along the creases and assembles the box. Some models can also attach additional components, such as magnetic closures or ribbons.

5.Output

The finished boxes are ejected from the machine, ready for quality inspection and packaging.

1.Cost-Effective Production

By automating the box-making process, these machines significantly reduce labor costs and minimize material waste. This makes them a cost-effective solution for businesses of all sizes.

2.Consistent Quality

The precision and consistency of an Automatic Rigid Box Maker ensure that every box meets the highest quality standards. This is especially important for luxury brands that require flawless packaging.

3.Scalability

Whether you’re producing small batches or large volumes, an Automatic Rigid Box Maker can scale to meet your needs. This flexibility makes it a valuable investment for growing businesses.

4.Spare parts support

Positive Run offers its customers a full one vear warranty on the machines it sells, andour spare parts are shipped within 24 hours as standard. lf there is a problem with aPositive Run machine covered by the terms of the warranty and the problem is causedby a manufacturing or material defect, we will provide you with free service under theterms and conditions of this warranty.

5.Remodeling & Upgrading

Zhengrun offers upgrades and modifications to cartoning machinesystems to improve the performance and extend the life of your purchased cartoningmachinery.

Automatic Rigid Box Makers are used in a variety of industries, including:

1.Luxury Goods: High-end cosmetics, perfumes, and jewelry.

2.Electronics: Smartphones, watches, and accessories.

3.Retail: Gift boxes, shoeboxes, and display packaging.

4.Food and Beverage: Premium chocolate, wine, and gourmet products.

The Automatic Rigid Box Maker is a game-changer in the packaging industry. Its ability to produce high-quality, durable boxes with speed and precision makes it an indispensable tool for businesses that value efficiency and excellence. Whether you’re a manufacturer looking to streamline your production process or a brand seeking to elevate your packaging, investing in an Automatic Rigid Box Maker is a decision that will pay off in the long run.

If you’re in the market for a reliable and efficient box-making solution, look no further than our company. With 25 years of production experience, we specialize in the research, design, manufacturing, and box-making equipment. Our strong technical expertise and extensive industry knowledge enable us to deliver high-quality machines tailored to meet the diverse needs of our clients. Whether you’re producing luxury packaging, electronics, or retail boxes, our advanced solutions are designed to optimize your production process and enhance efficiency. Explore our website to discover a wide range of innovative solutions and find the perfect machinery to elevate your business and keep you ahead of the competition.

We have the latest advanced processingequipment and international lean productionprocess, and strive to be the industry leader.