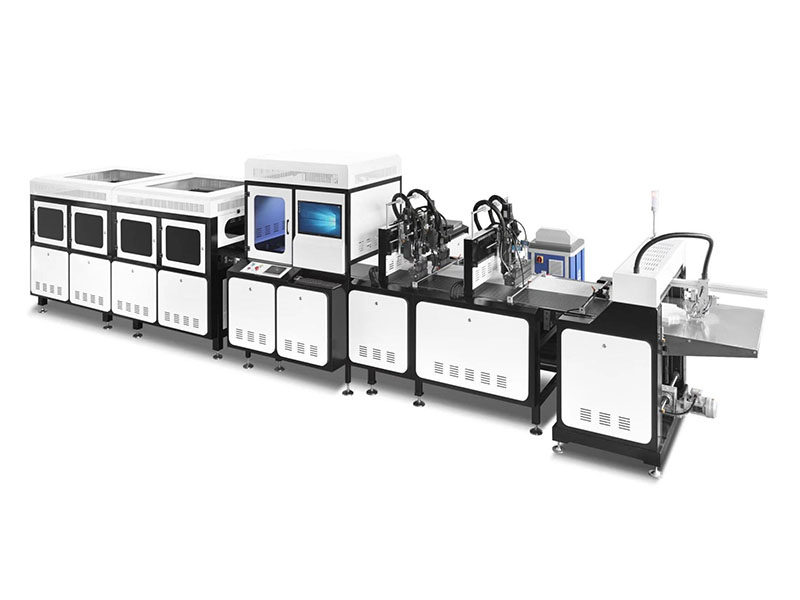

ZR-800 fully intelligent folding box machine consists of feida paper delivery, glue, cardboard visual positioning, package edge, assembly of five institutions.

20

boxs / min

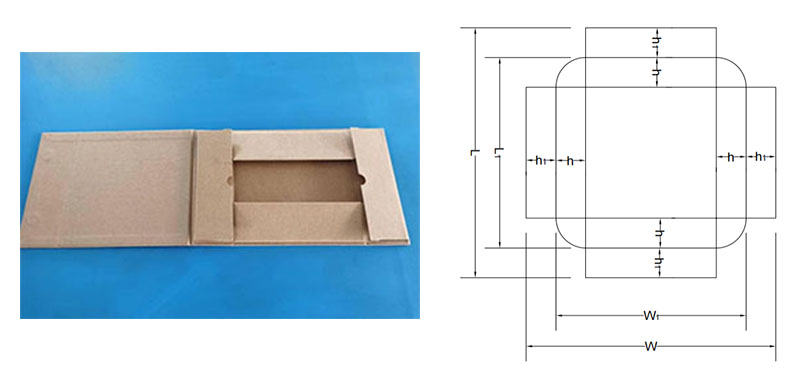

Plate is A, both side plate is B

ZR-800 intelligent folding box machine, using the most advanced 68-bit processor and optimized software algorithm, to achieve high precision automation performance

Humanized digital interface, equipped with a 21-inch touch screen, simple and easy to use

The most advanced high-speed local scraping process replaces the traditional spray line method, making the glue on the paper surface more consistent

The needle valve can accurately cut off the glue flow

This machine adopts high temperature melt glue to ensure the efficiency and quality of the box One, overview

1, ZR-800 fully intelligent folding box machine consists of feida paper delivery, glue, cardboard visual positioning, package edge, assembly of five institutions. This machine Feida adopts full pneumatic after paper separation, front suction stability, PLC control, simple operation, paper platform has paper correction function, the glue part design is reasonable, the system automatic compensation function, make the glue uniform, the new design of paper wrap edge way, make the paper more uniform, durable. There is a high-power fan under the conveyor belt, adsorption paper for smooth transmission, surface paper using optical visual positioning, cardboard conveying using linear guide rail, servo motor transmission, using a manipulator to grasp,And can locate the box for correction.

This machine is mainly used in cosmetics folding box, gift folding box, shoebox folding box, book folding box and other fields, with the beautiful finished products, high efficiency, accurate accuracy, low transportation cost, low storage space and other characteristics.

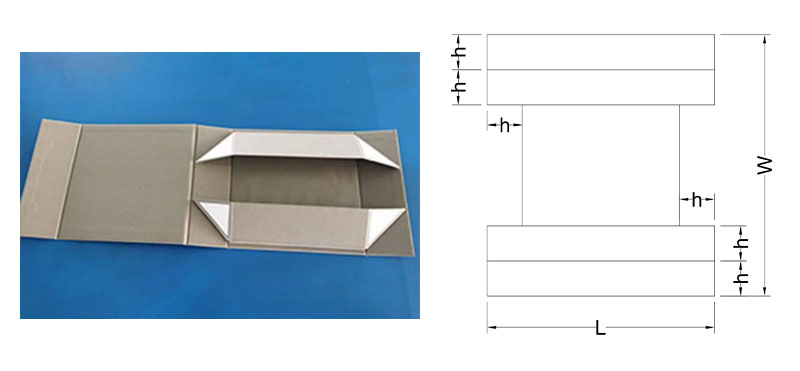

2. The second major feature of this machine is that it can automatically produce two different structures of folding boxes, one is the two-side plate structure, the other is the four-side plate structure, the four-side

|

Project Name |

Parameters |

Unit |

|

Mechanical dimensions (L*W*H) |

11000*2200*2000 |

mm |

|

Voltage |

380 |

v |

|

Motor Power |

19.5 |

KW |

|

Enter air pressure |

5-8 |

bar |

|

Production speed |

20 |

ps/h |

|

Ultimate capacity |

15 |

L |

|

Maximum paper height |

380 |

mm |

|

Progam matically |

Teach programming |

|

|

Machine weight |

4500 |

KG |

|

Paper size |

230*230-750*750 |

mm |

|

Paper width |

190*190--640*640 |

mm |

|

Paper thickness |

1-3 |

mm |

|

Paper pieces |

4 |

pcs |

|

Caron size |

20--120 |

mm |

|

Caron height |

35-120 |

mm |

|

Cardboard length |

220--350 |

G |

|

Cardboard height |

(L-h-h1)*(W-h-h1)*h |

mm |

|

Glue piece |

0-8 |

pcs |

|

Cover size |

120*190-450*1000 |

mm |

|

Cover thickness |

1-3 |

mm |

|

Glue thickness |

0.05-0.15 |

mm |

B Type (Parameter)

|

Paper size L*W |

190*260--540*750 |

mm |

|

Reduced depth |

120--250 |

G |

|

Paper thickness |

1-3 |

mm |

|

Paper pieces |

2 |

pcs |

|

Caron size |

(L-2h)*(w-4h) |

mm |

|

Caron height |

35-120 |

mm |

|

Glue piece |

0-8 |

pcs |

|

Cover size |

120*190-450*1000 |

mm |

|

Cover thickness |

1-3 |

mm |

|

Glue thickness |

0.05-0.15 |

mm |

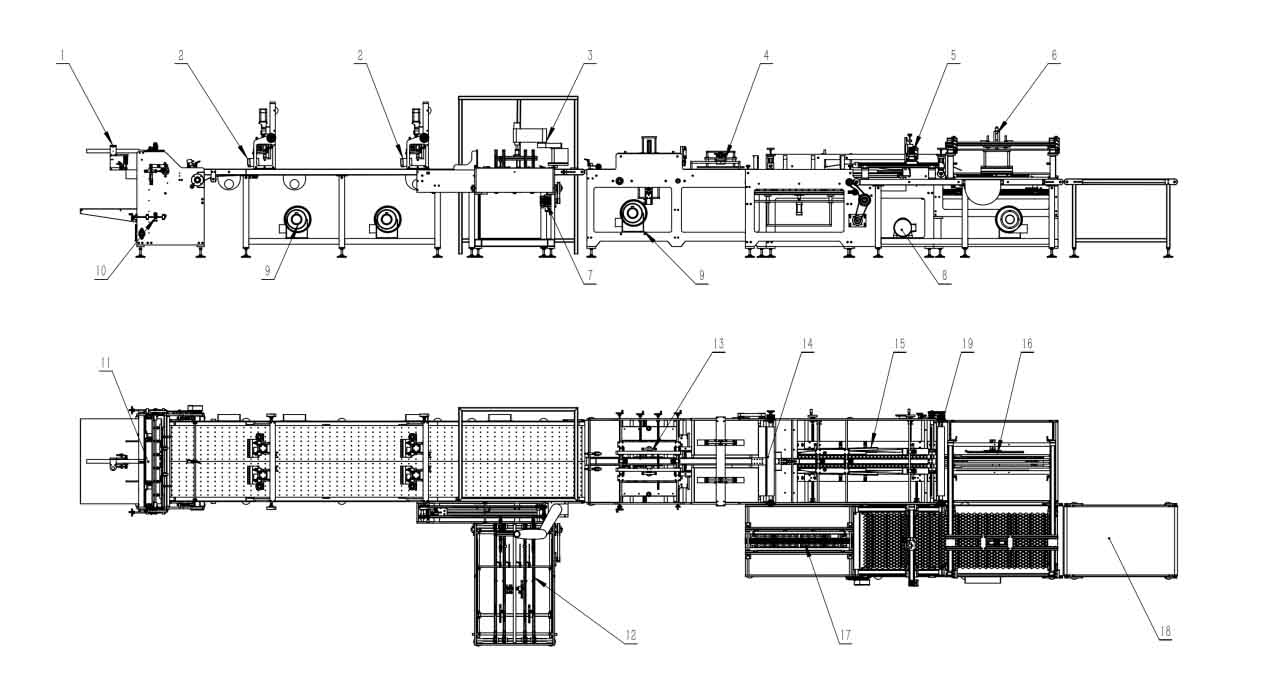

1.Feida: according to the cylinder lifting nozzle to adsorb the inner box of paper

2.Double scraper: the scraper position can be adjusted according to the leather of the inner box

3.Mechanical arm: adsorption paper sheet

4.Cardboard leveling device: the leveling width can be adjusted

5.Leather spray touch: according to the size of the shell can write spray starting point, finishing position

6.Inner box and shell assembly: can adsorb the box stick to the shell flattening

7.Servo motor: drive the paper to the limit position with the mechanical arm adsorption

8.Three-phase motor deceleration motor

9.Centrifugal fan: according to the duct

10.Interlace spiral gear device: adjustable according to the leather size of the inner box

11.Fel: according to the leather size of the inner box

12.Push and pull sheet device: driven according to the servo motor

13.Jture cylinder lower leveling device: Push to press the leather of the lower pressure cylinder according to the clamp cylinder

14.Press paper roller: adjust according to the thickness of the inner box

15.0 ~90 ~0 Fding ding unit

16.The inner box leather case adjusts the limit position

17.Adsorption shell conveying device: according to the size of cardboard adsorption conveying to the glue touch head position

18.Delivery frame device: the carton is bonded and transported to the manual position

19.Delivery roller: drive the inner box shell conveying

Rising platform part: including Fida, rising platform frame, adjustable left and right baffle, adjustable paper card corner device, paper front suction nozzle inlet device, paper rubber roller device.

Paper conveying scraper part: double detector, optical eye device, front and rear paper scraper can be adjusted double touch head, paper side corner scraper can adjust small touch head, paper left and right side can be adjusted double touch head.

Visual system section:

Gray board conveying device part: ash plate conveying adjustment device, front ash plate conveying adjustment device, mechanical arm nozzle fitting device.

Paper folding edge part: photoelectric detection pressure wheel device, correcting edge positioning device, cylinder positioning pressure side device, adjusting the rising pressure side device.

Paper secondary folding edge part: forming folding edge plate device.

Paper board correction part: cylinder adjustment card edge device, belt moving device.

Group installed part: adsorption cardboard adjustment device, cardboard placement card slot adjustment device.

Transmission spray adhesive part: movable spray head device, fine tuning card edge device, mobile adsorption left and right module device.

We have the latest advanced processingequipment and international lean productionprocess, and strive to be the industry leader.