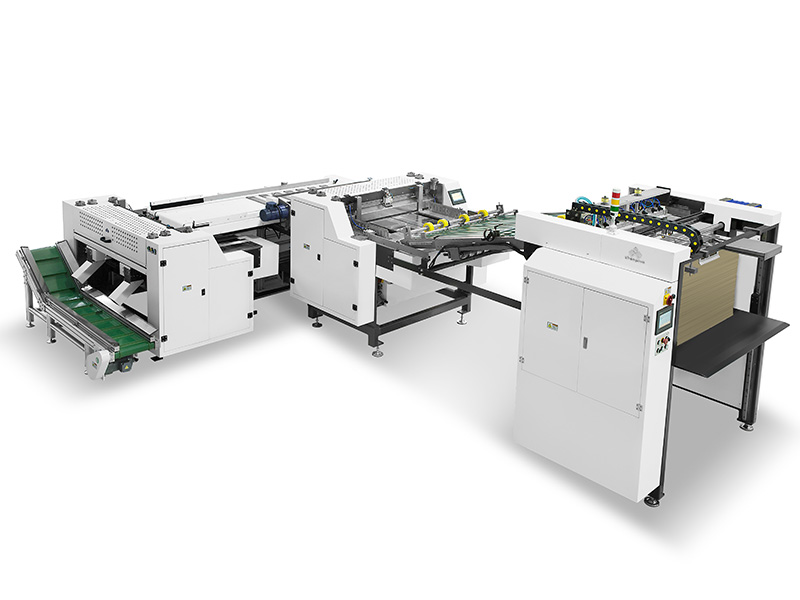

Auto Board Feeder

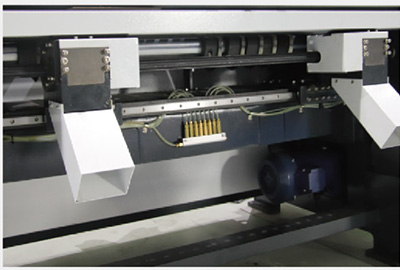

It adopts bottom drawing type non-stop feeder, which is suitable for small size material cutting.

It Can automatically feed and glue paper, delivery and position cardboard,and fold four sides in one process; there are features of accurate and quick positioning, and beautiful finished products etc.

Open Plate ≤25/Opening Small Plate ≤120

boxs / min

It is used to make hardcovers, notebook covers, desk calendars, hanging calendars, book-type boxes, files and rregular covers etc.

1. The big cardboard is fed by hand, automatic feeding for small cardboard. Servo controlled and setup via touch screen.

2. Pneumatic cylinders control the pressure, easy adjustment of cardboard thickness.

3. The safety cover is designed according to European CE standard.

4. The concentrated lubrication system, easy to maintain.

5. Main structure is made of casting iron, stable without bending.

6. The crusher could cut the waste into small size and convey them out of the machine by belt.

7. With a 2 meter conveyor belt for collecting.

|

型号 |

Model |

FD-KL1300ASB |

|

纸板宽度 |

Board Width |

550mm< W<1300mm L <900mm W1<100-600mm, W2<55-600mm |

|

堆纸高度 |

Stacking Height |

1300mm |

|

纸板厚度 |

Cardboard Thickness[T] |

1-3mm |

|

裁切速度(开大板) |

Cutting Speed (Open Plate) |

≤25张/min |

|

裁切速度(开小板) |

Cutting Speed (Opening Small Plate) |

≤120张/min |

|

电机功率 |

Motor Power |

1.5kw/380v 3phase |

|

总功率 |

Total Power |

8kw/380v 3phase |

|

气源要求 |

Air Supply |

0.2L /min 0.6Mpa |

|

机器重量 |

Machine Weight |

3500kg |

|

机器尺寸 |

Machine Dimension |

L5780xW4250xH1770mm |

It adopts bottom drawing type non-stop feeder, which is suitable for small size material cutting.

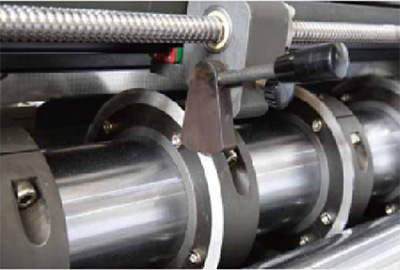

Using alloy material round knife, durable,effectively reduce wear and improve cutting efficiency.

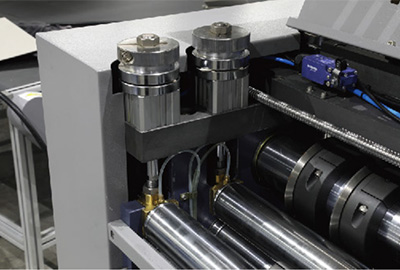

Pneumatic pressure adjustment, conve-nient and fast, reduce the technical personnel on the machine operation requirements.

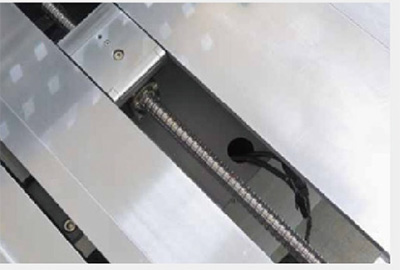

The feeder adopts servo motor and ball screw, which improves the accuracy and makes the adjustment easier.

Digital setting of knife spacing. according to the setting, the gauge automatically moves to the designated position, easy to adjust, no need to measure.

After the board is cut, the left and right wastes are automatically send to the crusher, and then conveyor belt send them out of machine, which is simple and practical, and reduces the labor intensity

We have the latest advanced processingequipment and international lean productionprocess, and strive to be the industry leader.