Glue Viscosity Control Configuratlon (Optional)

Auto glue viscosity meter efficiently adjusts the glue stickiness which ensures the quality of finished products.

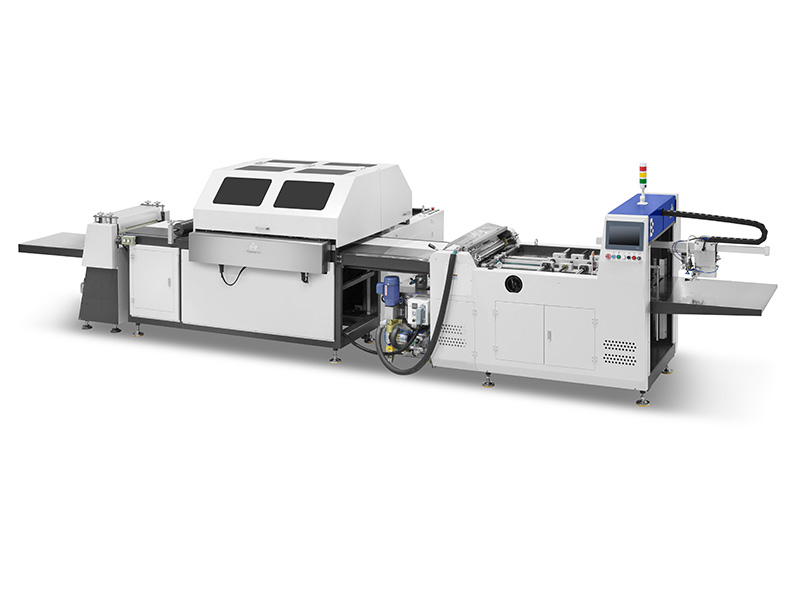

It Can automatically feed and glue paper, delivery and position cardboard,and fold four sides in one process; there are features of accurate and quick positioning, and beautiful finished products etc.

The lining machine is an equipment especially designed for die cutting the ordinary cardboard, corrugated board, plastic and leather products. It is widely used in the printing, packing decorating and plastic industries. The machine has features such as compact structure, fine workma.

<38

boxs / min

It is used to make hardcovers, notebook covers, desk calendars, hanging calendars, book-type boxes, files and rregular covers etc.

1. High strength due to one piece casting by using top quality materials for themachine body.

2. Smooth running, big pressure and low noise are obviously remarked as herringbone gear input and helical gear output mechanism is adopted.

3. Single plate electromagnetic clutch is sensitive and reliable.

4. Operational altitude is reasonably arranged, moveable platen opens to its optimum.

5. The electrical system is designed with IEC standard.

6. With functions as single, continuous operation and opening well, and the dwell time is adjustable.

7. The safely system is reliable.

8. With concentrated lubricating system.

| Model | CM540S |

| Case Size (W×L) | Min.100×200mm Max.540×1000mm |

| Paper Thickness | 100~300g/m² |

| Cardboard Thickness (T) | 0.8~4mm |

| Precision | ±0.1mm |

| Speed | <38pcs/min |

| Motor Power | 9kw/380v 3phase |

| Electric Heating Power | 12kw |

| Air Supply | 10L/min 0.6Mpa |

| Machine Dimension | L6700×W2400×H1700mm |

| Machine Weight | 2200kg |

1.The max and mini sizes of the covers are subjected to the size and the quality of the paper.

2.The speed of the machine depends on the sizes of the covers.

3.We don't provide air compressor.

Auto glue viscosity meter efficiently adjusts the glue stickiness which ensures the quality of finished products.

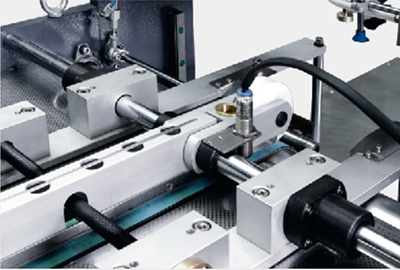

The ultrasonic double paper detector ensures the machine running and reduces the waste.

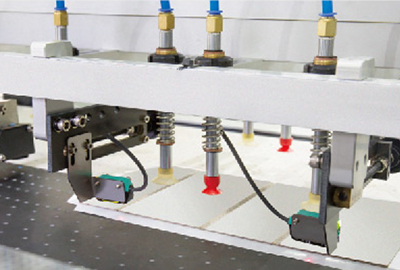

Photoelectric Tracking Detection, Servo Deviation Correction To Ensure Position-ing Accuracy.

Non-stop downward suction type cardboard feeding device efficiently ensures the products without scratches.

We have the latest advanced processingequipment and international lean productionprocess, and strive to be the industry leader.