The automatic cover machine produced by our company has the characteristics of fast production speed, less labor, beautiful finished products and high precision.

≦38

boxs / min

Products can be widely used in the production of hardcover book cover, notebook, folder, desk calendar, wall calendar, packaging gift box and other fields.

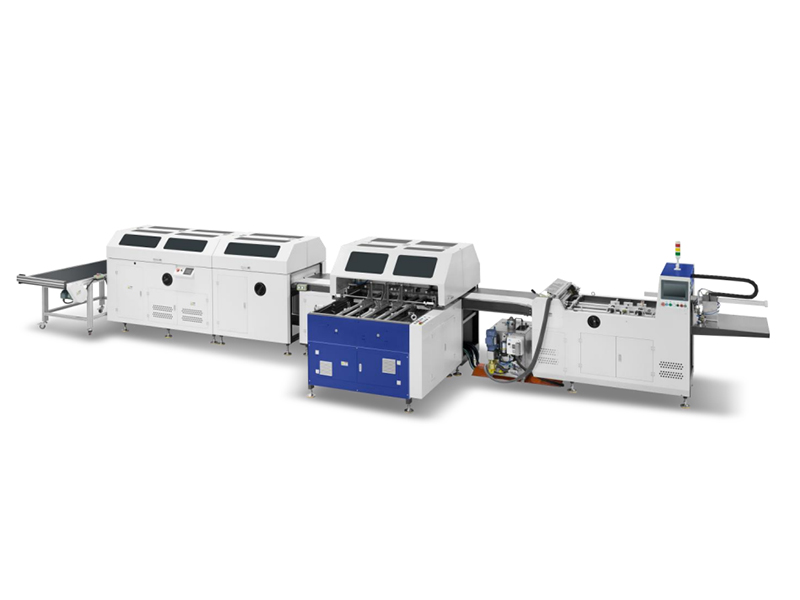

Automatic Case Maker

At present, the factory is basically handmade and semi-mechanized production, which requires a large number of labor forces, a large number of labor forces need to carry out human resources management, and these labor forces are some ordinary female workers, their own poor quality, low cultural level, management difficulty, many bosses and managers are also miserable.

The automatic cover machine produced by our company has the characteristics of fast production speed, less labor, beautiful finished products and high precision. Products can be widely used in the production of hardcover book cover, notebook, folder, desk calendar, wall calendar, packaging gift box and other fields.

system composition

Product name:Automatic Case Maker

Model:CM450A

Main accessories:

PLC system: INOVANCE PLC system

Drive system:Taiwan yintai

Low-voltage electrical components:French SCHENIDER

Transducer:French SCHNEIDER

Pneumatic element:Taiwan AIRTAC

Photoelectric color marking element:Germany SICK

Ultrasonic double paper detection:Germany PEPPERL+FUCHS

Conveyer belt:Switzerland HABASIT

Servo Motor:China INOVANCE

Timing belt:Germany CONTIECH

Gear motor:Taiwan Dongli

Bearing:import NSK bearing

Gluing roller:Chromium plated stainless steel (new process)

Another accessory:Vacuum pump ORION

Function:

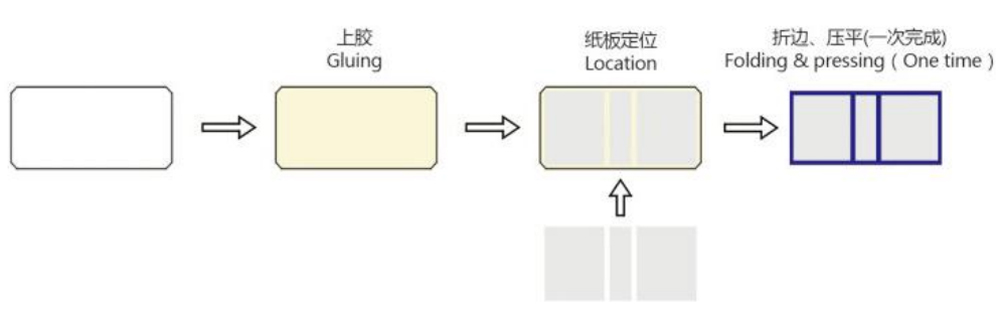

(1)Paper is automatically glued

(2)Automatic transfer of cardboard positioning and fitting

(3)One fold on all four sides

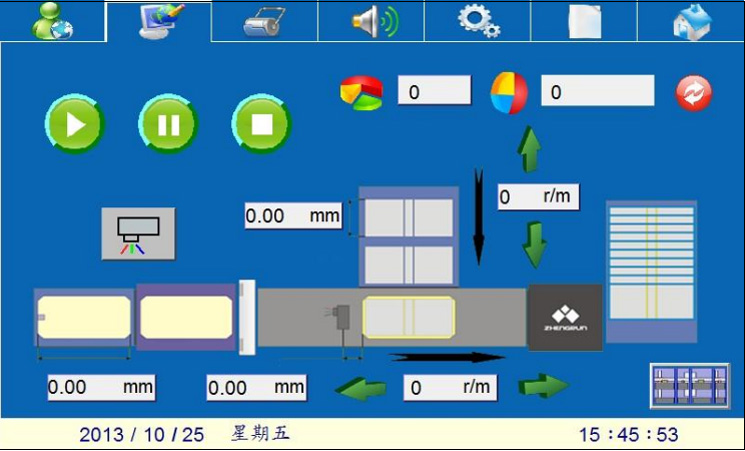

(4)User-friendly graphical man-machine interface, displayed on all faulty computers

(5)The integrated safety cover is designed according to the European CE standard, which is safer and more humane

User-friendly interface

(1)paper gluing machine:

Full pneumatic Feeder head: simple structure, easy operation, novel design, PLC control, accurate action (in China is the first good, is the invention patent of our company)

Paper conveying adopts ultrasonic double-sheet paper detection device

The valve can be changed quickly, and the rubber roll cleaning takes only 3-5 minutes

(2)cardboard transfer part:

When the cardboard conveying is short, there is an automatic detection device (when several pieces of cardboard are sent at the same time, less than one or several pieces of cardboard, the machine will stop and alarm

(3)position part:

Paper conveying adopts servo motor drive and high-precision photoelectric positioning

The conveyor belt is provided with a high-power suction fan, so that the paper can be smoothly adsorbed on the conveyor belt

The on-line action is controlled by PLC

A pre-pressing roller is provided above the conveyor belt to keep the cardboard and face paper fit before folding

(4)Hem on all four sides:

The left and right sides of the film base band fold

The flanged part adopts the front and rear split double drive servo motor, synchronous no displacement, no scratch

|

|

Model |

CM450A |

|

1 |

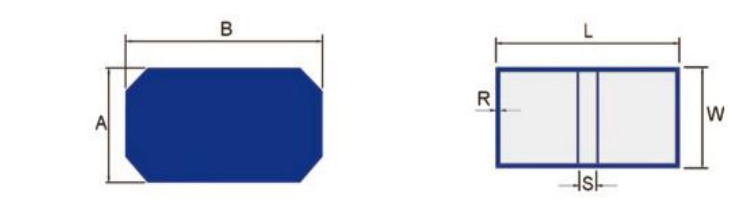

Paper size(A×B) |

MIN: 130×230mm MAX: 480×830mm |

|

2 |

Paper thickness |

100~300g/m2 |

|

3 |

Cardboard thickness (T) |

1~3mm |

|

4 |

Product size (W×L) |

MIN: 100×200mm MAX: 450×800mm |

|

5 |

Minimum size of center strip (S) |

10mm |

|

6 |

Fold into paper edge size(R) |

10~18mm |

|

7 |

Cardboard qty.(max.) |

6pieces |

|

8 |

Precision |

±0.10mm |

|

9 |

Speed |

≦38sheets/min |

|

10 |

Motor power |

12kw/380v 3phase |

|

11 |

Electric power |

12kw |

|

12 |

Air supply |

30L/min 0.6Mpa |

|

13 |

Machine weight |

3200kg |

|

14 |

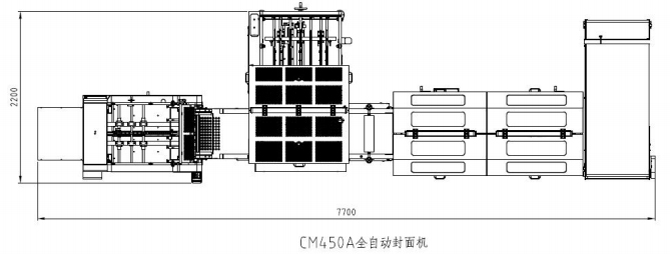

Machine size (L×W×H) |

L7700×W2200×H1700mm |

The maximum and minimum size of the cover also depends on the maximum and minimum size of the paper and the quality of the paper

The speed is 30 covers per minute, but the size of the cover will affect the speed of the machine

Maximum stacking height of cardboard:220mm

Maximum stacking height of paper:280mm

The capacity of the rubber bucket:60L

Production flow diagram:

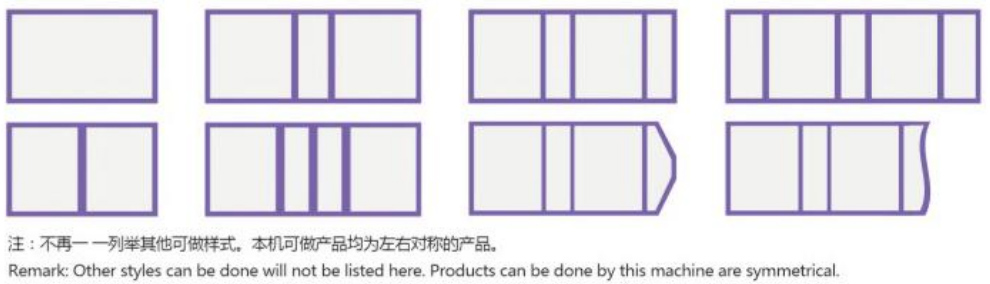

Sample:

Sample:

Purchase instructions

1、 Foundation requirements

The machine should be installed on a flat and solid ground to ensure that the ground has enough bearing capacity (about 300kg/m2), and sufficient operation and maintenance space should be reserved around the machine.

2、Machine size

3、Environmental conditions

Temperature: The ambient temperature must be maintained at about 18-24°C (air conditioning equipment is required in summer)

Humidity: The ambient humidity should be controlled at about 50%-60%

Lighting: above 300LUX to ensure the normal operation of photoelectric components

Keep away from oil and gas, chemicals, acidity, alkalinity and explosives or inflammables

Avoid proximity to machines that produce vibration and high frequency electromagnetism

Avoid direct sunlight

Avoid direct fan blowing

4、Material requirements

Paper and paperboard must be kept flat, and necessary moisture-proof and wind-dry measures must be taken

Both sides of the paper must be treated by electrostatic discharge

Board slitting error should be controlled within ±0.20mm (recommended to use the board slitting machine KL1300 and the center slitting machine ZX450)

5、If the color of the adhesive surface on the face paper is close to or the same as that of the conveyor belt (black), adhesive tape of other colors must be affixed to the conveyor belt to distinguish the color label (generally, as long as the width of the adhesive tape is about 10mm below the color label, the color is recommended to choose white).

6 、Power requirements: three-phase 380V/50Hz/40A voltage (special cases need to be customized, can be explained in advance, such as: 220V, 415V and other countries voltage).

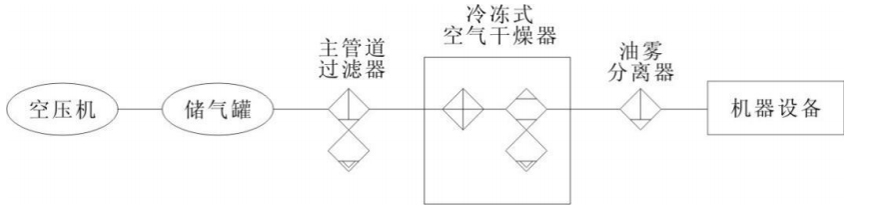

7、Air source: 5-8 Atmospheres (atmospheric pressure), 10L/min. Poor air quality is the main reason for the failure of the pneumatic system, which will greatly reduce the reliability and service life of the pneumatic system, and the resulting loss will greatly exceed the cost and maintenance costs of the air source treatment device, so the correct configuration of the air source treatment system and its components is very important. The following air purification treatment options are available for reference (by the user):

Air compressor is referred to as air compressor, it is not a standard part of the machine, the machine does not provide air compressor when the factory, ordered by the customer. The power of the air compressor is 11KW and the air flow rate is 1.5m3/min.

The role of the gas storage tank (capacity 1m3, atmospheric pressure 0.8MPa):

a.Through the gas storage tank can condense part of the high temperature gas from the air compressor

b.Maintain the pressure stability of the rear actuator using the pneumatic element

The function of the main filter is to remove oil, water and dust in the compressed air to improve the working efficiency of the downstream dryer, and extend the use time of the rear precision filter and dryer

The role of the refrigerated air dryer is to remove the water in the compressed air after the compressed air is processed by the post-cooler, oil-water separator, gas tank, and main flow filter

The role of the oil mist separator: further out the water in the compressed air after being treated by the cold dryer

8、Staffing: In order to ensure man-machine safety, and give full play to its performance, reduce failures, extend service life, it is necessary to be equipped with dedicated, capable and has a certain degree of mechanical equipment operation, maintenance capabilities of 2-3 people.

9、auxiliary materials

Glue: animal glue (jelly glue, gel glue), specification: high speed and fast drying type

We have the latest advanced processingequipment and international lean productionprocess, and strive to be the industry leader.