Booth No: W3-001-B

Time: May 15-19,2025

Add: China international Exhibition Center (shunyi Hall), Beijing

Booth No: W3-001-B

Time: May 15-19,2025

Add: China international Exhibition Center (shunyi Hall), Beijing

According to the market demand, our company will cover machine and the lining machine through the turning linkage, to achieve the shell lining molding, convenient and fast, save time and effort.

≦30

boxs / min

Products can be widely used in the production of hardcover book covers, notebooks, folders, desk calendar, wall calendar, packaging gift boxes and other fields.

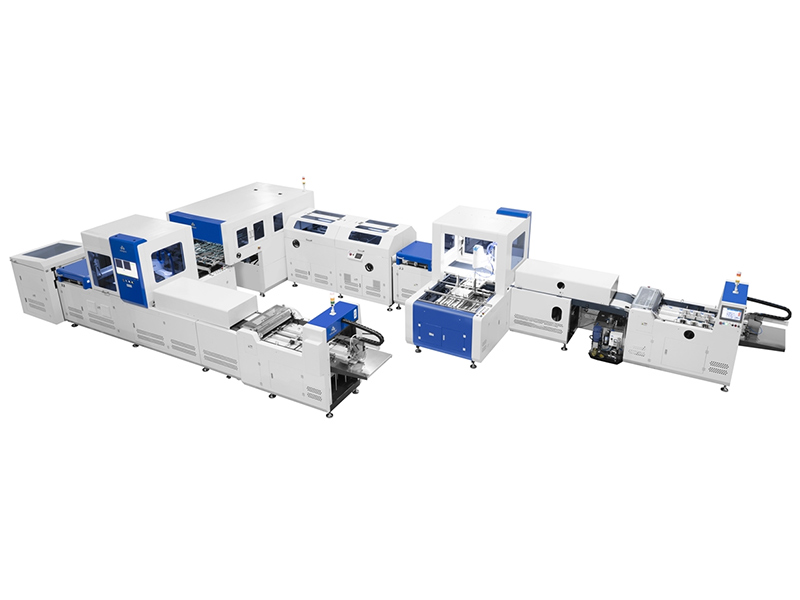

Automatic cover all-in-one machine brief introduction

According to the market demand, our company will cover machine and the lining machine through the turning linkage, to achieve the shell lining molding, convenient and fast, save time and effort. It has the characteristics of fast production speed, less labor required, beautiful and delicate finished products, and high precision. Products can be widely used in the production of hardcover book covers, notebooks, folders, desk calendar, wall calendar, packaging gift boxes and other fields.

Product name: Fully automatic visual cover integrated machine

Model number: CBD 540

Main accessories:

PLC system: the Omron OMRON PLC System, Japan

Transmission system: Yintai, Taiwan

Low-voltage electrical components: Eaton EATON

Inverter: Schneider SCHNEIDER

Pneumatic element: SMC, Japan

Photoelectric color standard element: SICK, Germany

Ultrasonic double paper detection: Germany Baomeng BAUMER

Conveyor belt: Hubster H ABASIT, Switzerland

Servo motor: Huichuan INOVANCE

Synchronous belt: German horse brand CONTIECH

Reducelermotor: Taiwan Eastern calendar

Bearing: imported NSK bearings

Rubber roller: adopt stainless steel chrome plating (new process)

Other accessories: Holwang Vacuum Pump ORION

Basic functions:

(1) Face paper will automatically transport the glue

(2) Board automatic delivery and positioning fit

(3) Four sides are formed at one time

(4) After the cover is automatically flipped to the lining machine

(5) lined cardboard using cardboard suction before push feeding

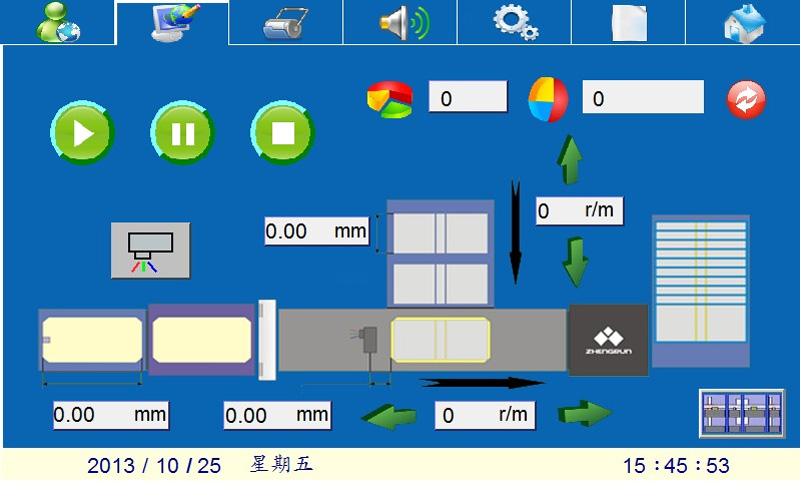

(6) Friendly graphics man-machine operation interface, all the fault computer are displayed

(7) The integrated safety cover is designed according to the European CE standard, which is safer and more humanized

Friendly human-machine operation interface

3、the constitution of mechanism:

1. Fully automatic front cover machine

(1) Rubber part on the paper:

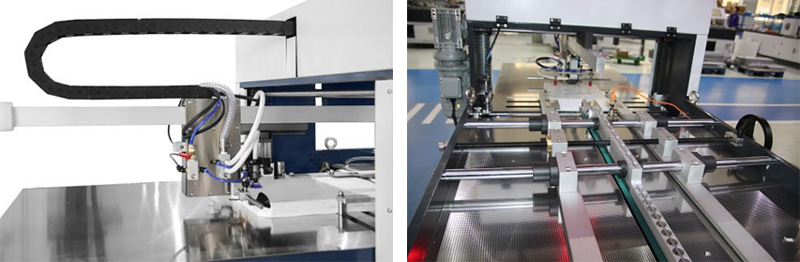

Full pneumatic feida head: simple structure, convenient operation, novel design, PLC control, accurate action (it is the first in China, is our invention patent)

The rubber bucket has constant temperature heating, filtration, circulation of glue, and with automatic mixing device (white rubber hot melt glue double use)

Can quickly convert valves, rubber roller cleaning only 3-5 minutes

(2) Cardboard conveying section:

When the cardboard conveying is missing, there is an automatic detection device (when several pieces of cardboard are sent at the same time, one or several pieces of cardboard are missing, the machine will stop the alarm)

(3) Positioning lamer:

Face paper conveying adopts servo motor transmission, high precision, photoelectric positioning

A high-power suction fan is provided under the conveyor belt, so that the surface paper can be smoothly adsorbed on the conveyor belt

Online action is controlled by the PLC

A prepress roller is provided above the conveyor belt to keep the cardboard and the paper close before folding the edge

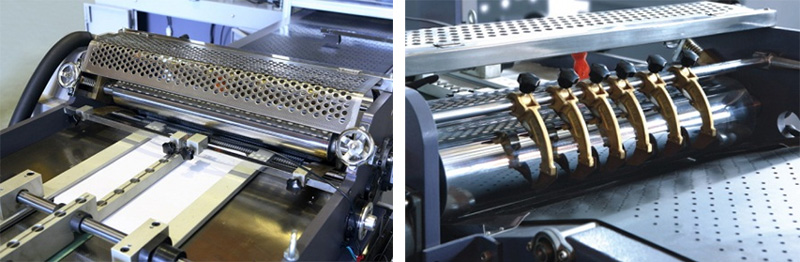

(4) Four-sided folding:

The left and right sides of the sheet base band folded edge

The folding part adopts front and rear split drive servo motor for synchronization without displacement and scratching

Using a non-adhesive Teflon roller multilayer leveling

2. Flip part:

Using servo motor

Using Taiwan Shenli planetary reducer deceleration, high precision

3.Automatic mounting and lining machine:

(1) Rubber part on the paper:

Full pneumatic feida head: simple structure, convenient operation, novel design, PLC control, accurate action (it is the first in China, is our invention patent)

Ultrasonic double-sheet paper detection device is used for surface paper delivery

Face paper deviation correction device, to ensure that the surface paper is not offset after the glue

The adhesive roller is made of stainless steel chrome roller, and the wire contact scraper is more durable

The rubber bucket has constant temperature heating, filtration, circulation of glue, and with automatic mixing device (white rubber hot melt glue double use)

Can quickly convert valves, rubber roller cleaning only 3-5 minutes

(2) Cardboard conveying section:

Board conveying using the bottom extraction structure, in the machine does not stop, cardboard can be added at any time

When the cardboard conveying is missing, there is an automatic detection device (when several pieces of cardboard are sent at the same time, one or several pieces of cardboard are missing, the machine will stop the alarm)

(3)Positioning lamer:

Face paper conveying adopts servo motor transmission, high precision, photoelectric positioning

A high-power suction fan is provided under the conveyor belt, so that the surface paper can be smoothly adsorbed on the conveyor belt

Board / carton delivery using Yamaha manipulator, dual camera HD image positioning, accuracy of (± 0.1) mm.

Online action is controlled by the PLC

A prepress roller is provided above the conveyor belt to keep the cardboard and the paper close before folding the edge

(4) Piping section:

With five pressure roller can effectively remove the bubbles in the cover, flattening and with pressure groove function, without secondary processing, make the product smooth and beautiful.

|

|

Model |

CBD540 |

|

1 |

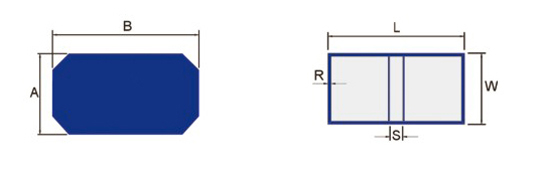

Paper size(A×B) |

MIN: 150×250mm MAX: 570×1030mm |

|

2 |

Paper thickness |

100~300g/m2 |

|

3 |

Cardboard thickness (T) |

1~3mm |

|

4 |

Box size (W×L) |

MIN: 100×200mm MAX: 540×800mm |

|

5 |

size of center strip min. (S) |

7mm |

|

6 |

Fold into paper edge size(R) |

10~18mm |

|

7 |

Cardboard qty. |

6pieces |

|

8 |

Precision |

±0.10mm |

|

9 |

Speed |

≦30sheets/min |

|

10 |

Motor power |

23kw/380v 3phase |

|

11 |

Electric power |

24kw |

|

12 |

Air supply |

55L/min 0.6Mpa |

|

12 |

Machine weight |

6500kg |

|

13 |

Machine size |

L 12800×W 3900×H 2000mm |

The maximum and minimum size of the cover depends on the maximum and minimum size of the paper and the quality of the paper

The speed is 30 covers per minute, but the size of the cover affects the speed of the machine

Maximum stacking height of cardboard: 220mm

Maximum stacking height of the paper: 280mm

Capacity of the rubber barrel: 60L

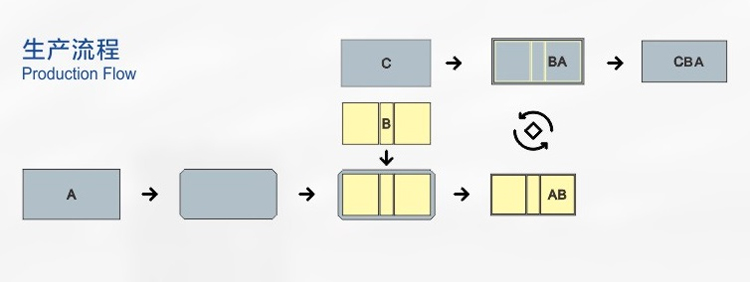

Production process schematic diagram:

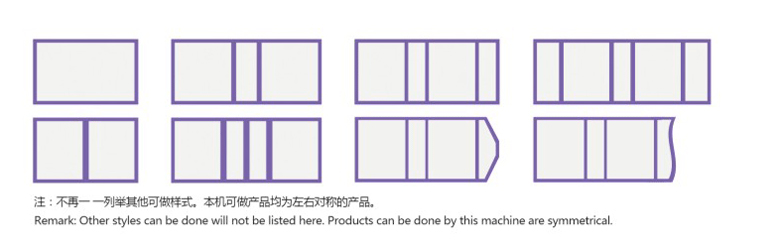

Product legend:

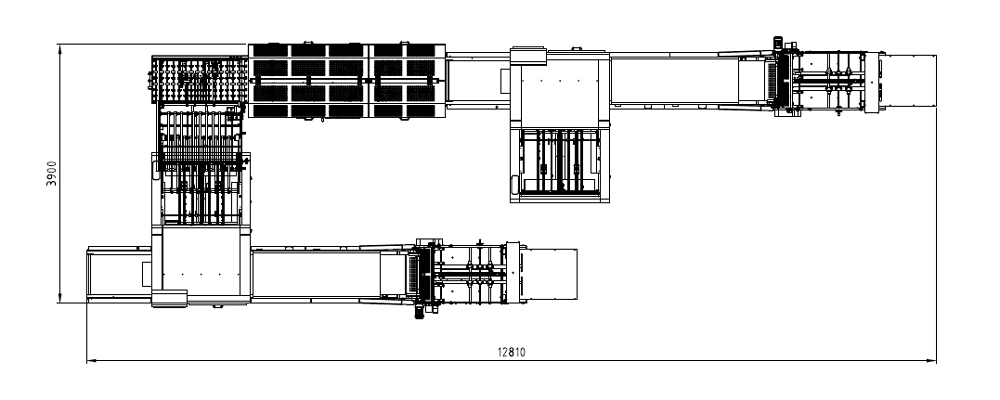

2, the size of the machine

3. Environmental conditions

Temperature: The ambient temperature must be kept around 18-24°C (air conditioning device should be provided in summer)

Humidity: the environmental humidity should be controlled at about 50% -60%

Lighting: above 300 LUX to ensure the normal operation of photoelectric components

Keep away from oil and gas, chemicals, acidic, alkaline and explosive or flammable

Avoid being adjacent to machines that produce vibration and high-frequency electromagnetic forces

Avoid direct exposure to the sun

Avoid direct fan blowing

4. Material requirements

Face paper, cardboard must be kept flat, do the necessary moisture-proof and windproof dry measures

The paper must be double-sided electrostatic treatment

The cardboard split error should be controlled within ± 0.20mm (it is recommended to use the cardboard split machine KL1300 and the center strip split machine ZX 450)

5. If the color of the adhesive surface on the paper is close to or the same as the conveyor belt (black), the adhesive belt must be affixed on the conveyor belt to make the color label distinguish (generally as long as the width of about 10mm is affixed below the color mark, the color is recommended to choose white).

6, power supply requirements: three-phase 380V / 50Hz / 40A voltage (special circumstances need to customize, can be explained in advance, such as: 220V, 415V, and other national voltage).

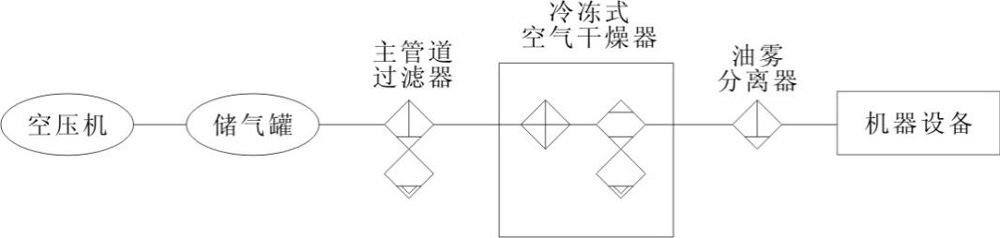

7, gas source requirements: 5-8atmospheres (atmospheric pressure), 10 L/min. Poor air quality is the most important reason for the failure of the pneumatic system, which will greatly reduce the reliability and service life of the pneumatic system, and the resulting loss will greatly exceed the cost and maintenance cost of the gas source processing device, so it is very important to correctly configure the gas source processing system and its components. The following air purification treatment scheme is available for reference (provided by the user):

Air compressor, for short, air compressor, it is not the standard accessories of the machine, the machine does not provide air compressor when the factory, ordered by the customer himself. The power of the air compressor is 11KW, and the air flow rate is 1.5 m3/min.

Action of gas storage tank (capacity 1m3, atmospheric pressure 0.8MPa):

a. The high temperature gas coming out of the air compressor can be condensed through the gas storage tank

b. Maintain the pressure stability of the pneumatic element

The function of the main road filter: remove the oil, water and dust from the compressed air, so as to improve the working efficiency of the downstream dryer, extend the use time of the rear precision filtration and dryer

The function of frozen air dryer: remove the moisture in the compressed air after the aftercooler, oil-water separator, gas tank, main circuit filter, etc

The role of oil mist separator: further moisture in the compressed air after the cold dryer

8, staffing: in order to ensure the safety of man and machine, and give full play to its performance, reduce faults, extend the service life, it is necessary to be equipped with dedicated, capable and with a certain mechanical equipment operation and maintenance ability of personnel 2-3 people.

9. Auxiliary materials

Glue: animal glue (jelly glue, curry glue), specification: high speed fast drying type

Ultrasonic double-sheet paper detection device is used for surface paper delivery

Face paper deviation correction device, to ensure that the surface paper is not offset after the glue

The adhesive roller is made of stainless steel chrome roller, and the wire contact scraper is more durable

The adhesive roller is made of stainless steel chrome roller, and the wire contact scraper is more durable

Board conveying using the bottom extraction structure, in the machine does not stop, cardboard can be added at any time

Board / carton delivery using Yamaha manipulator, dual camera HD image positioning, accuracy of (± 0.1) mm.

Board / carton delivery using Yamaha manipulator, dual camera HD image positioning, accuracy of (± 0.1) mm.

The corner is repaired by motor parts, which can make the corner effect more ideal

The corner is repaired by motor parts, which can make the corner effect more ideal

Lower suction type delivery board feida, scratch prevention (optional).

With five pressure roller can effectively remove the bubbles in the cover, flattening and with pressure groove function, without secondary processing, make the product smooth and beautiful.

With five pressure roller can effectively remove the bubbles in the cover, flattening and with pressure groove function, without secondary processing, make the product smooth and beautiful.

We have the latest advanced processingequipment and international lean productionprocess, and strive to be the industry leader.